Modern Drain Design and Evolving Expectations

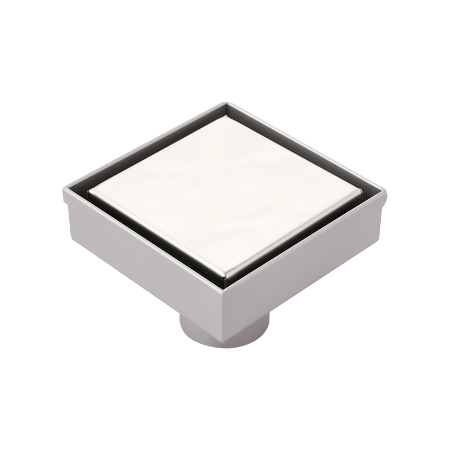

In contemporary construction and interior design, efficient drainage is a critical aspect, particularly in high-use areas such as bathrooms, kitchens, and utility rooms. With the rising demand for minimalist aesthetics and long-term durability, the Stainless Steel Tile Drain has become increasingly favored. Its flush-tile design and clean visual integration appeal to modern sensibilities, but functionality remains the key concern for homeowners and professionals alike. One pressing question is whether this sleek option provides good drainage speed compared to traditional floor drains. While design is important, performance under practical, everyday conditions is what truly defines value.

Engineering Behind Efficient Water Flow

Drainage speed is influenced by a combination of several factors, including surface slope, aperture size, drain geometry, and material friction. Stainless steel units often feature precision-cut openings, uniform slope alignment, and seamless channels, which collectively contribute to reducing flow resistance. These characteristics allow water to enter the drainage system rapidly and uniformly. In contrast, many traditional plastic or cast iron drains may have uneven or smaller grates, limited catch areas, or outdated designs that create turbulence and slow down water passage. Furthermore, traditional grates may trap debris more easily, which could cause clogging and hinder drainage speed over time.

Tile-Integrated Design Benefits

The integration of stainless steel drains with surrounding tiles offers more than visual consistency. The flat, unobtrusive surface reduces splashing and pooling, especially when paired with an accurately sloped floor. Because the opening area of a tile drain often spans a larger horizontal space compared to a small circular or square traditional drain, more water can flow in at once. This is particularly advantageous in wet rooms, walk-in showers, and laundry areas where sudden or heavy water flow is expected. By improving the initial intake of water and directing it efficiently to the pipes below, these drains can achieve faster overall evacuation rates.

Durability and Long-Term Flow Consistency

Another key aspect is how long a drainage system can maintain its original performance. Stainless steel resists corrosion, mineral buildup, and deformation caused by hot water or chemical exposure. Over time, this helps retain the smoothness of the drain surface and the integrity of the flow path. Traditional plastic or zinc alloy drains may degrade, warp, or become rough inside, which can create points of resistance and cause slower water movement. Maintenance also plays a role; stainless steel units are generally easier to clean and less likely to accumulate grime, which keeps the flow path unobstructed for longer durations.

Application and Testing in Real-World Environments

Tests conducted in both residential and commercial settings have demonstrated noticeable differences in performance. In high-flow environments such as gyms, spas, or multi-person households, tile-integrated stainless steel drains frequently outperform traditional units in draining both quickly and cleanly. Their consistent surface finish and streamlined profiles allow for more efficient channeling of water into the drainage system. Moreover, since many of these models are now engineered with anti-splash and anti-odor functions, they provide both fast drainage and hygienic operation—an essential combination for modern users.

A Clear Functional Advantage

While visual appeal may be the initial selling point, performance is what defines the lasting value of any drainage component. When considering drainage speed, stainless steel tile drains generally exhibit clear advantages over traditional alternatives due to improved intake design, smooth channeling, and lasting material integrity. Although actual performance may vary depending on floor gradient and installation quality, these units are more likely to deliver reliable, rapid water removal in both residential and commercial use. Therefore, for those prioritizing efficiency, investing in a tile-integrated stainless steel solution appears to be a practical and future-proof choice.