Stainless Steel Tile Drain is widely used in residential, commercial, and industrial environments, where it must withstand varying loads from foot traffic, furniture, or even heavy equipment. Understanding the compressive strength and overall load-bearing capacity is crucial for both designers and installers to ensure safety, longevity, and performance. An improperly selected drain can deform, crack, or fail under load, causing water pooling, structural damage, or costly repairs.

The load-bearing capability of a stainless steel tile drain depends on several key factors, including material grade, thickness, structural design, and installation method. Higher-grade stainless steel, such as 316 or 316L, typically exhibits good mechanical strength and corrosion resistance compared to 304-grade steel. Thickness plays a direct role: thicker drain covers and frames can support higher weights without deformation, while thinner components may flex or bend under moderate loads. Additionally, design features such as reinforced grids, crossbars, or honeycomb patterns can significantly enhance structural integrity.

Different stainless steel grades offer distinct mechanical properties. For example, 304 stainless steel is widely used due to its balance of strength, corrosion resistance, and affordability, but under loads, it may show slight deformation over time. In contrast, 316 stainless steel contains molybdenum, enhancing its strength and corrosion resistance, particularly in wet or chemical-exposed environments. The choice of material should consider both the expected load and environmental factors to maintain long-term performance.

Thickness is one of the straightforward indicators of load capacity. A drain cover with a thickness of 2 mm may support typical residential foot traffic, while a 4 mm or 5 mm thickness is recommended for commercial spaces with heavy pedestrian or trolley loads. Excessively thin covers risk bending under concentrated loads, potentially damaging the tile flooring and compromising drainage. Thickness must be matched with the overall structural design to prevent localized stress points from becoming failure points.

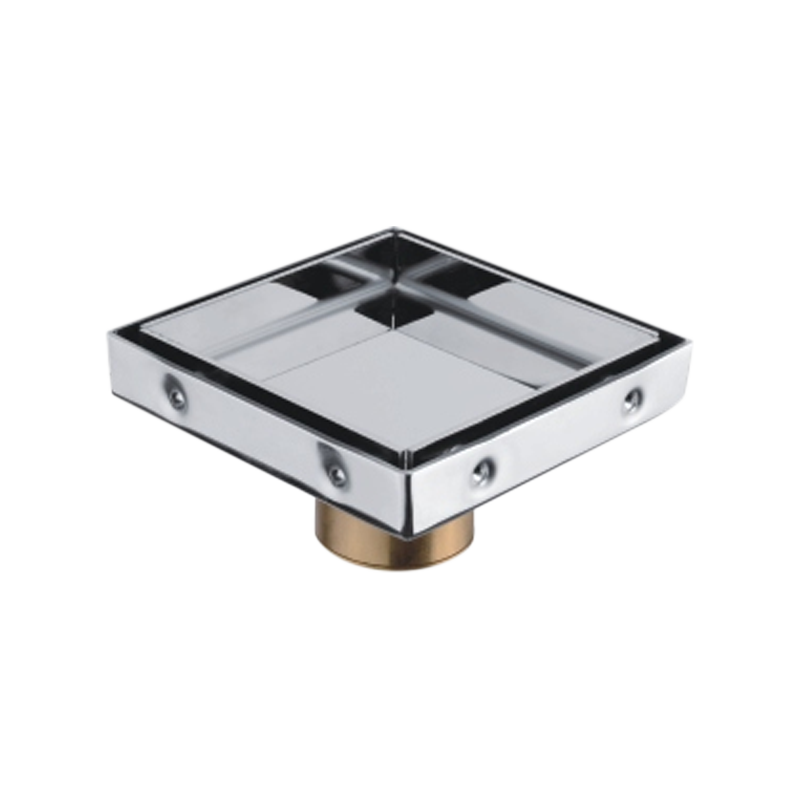

Beyond material and thickness, structural design plays a vital role in load performance. Stainless Steel Tile Drains can incorporate cross-supports, ribbing, or honeycomb patterns to distribute load evenly across the surface. Reinforced edges and mounting frames also help transfer weight to the surrounding floor structure, reducing stress on the drain itself. A well-engineered design ensures that even thinner drains can handle heavier loads safely, improving both durability and installation flexibility.

Load testing is essential to validate performance. Standardized tests simulate real-world conditions, applying uniform or concentrated loads to determine capacity without permanent deformation. Certifications or compliance with industry standards assure builders and end-users that the drain will perform as expected. By combining laboratory testing with material and design analysis, manufacturers can accurately specify the safe load limits for each product.

Evaluating the compressive and load-bearing capacity of a Stainless Steel Tile Drain requires careful consideration of material grade, thickness, structural design, and installation conditions. Different grades and thicknesses produce significant variations in strength and performance, making informed selection essential. By using high-quality materials, optimizing design, and validating through testing, manufacturers ensure that drains can withstand anticipated loads safely and reliably, protecting both the flooring and long-term drainage functionality. Properly selected and installed drains provide durability, safety, and peace of mind in a variety of applications.