Proper drainage is essential for both urban infrastructure and agricultural lands to prevent flooding, soil erosion, and structural damage.

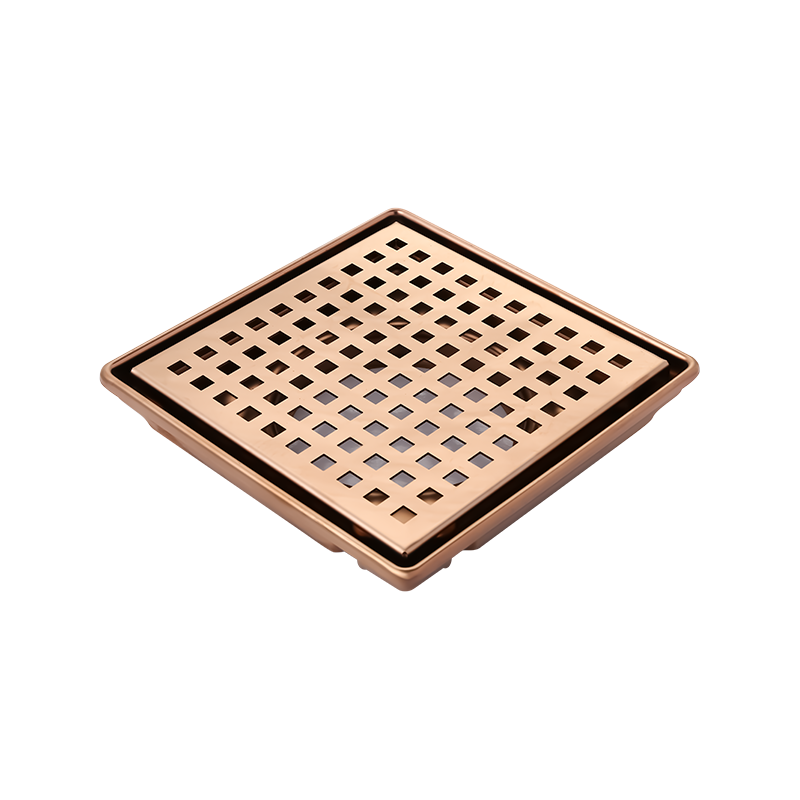

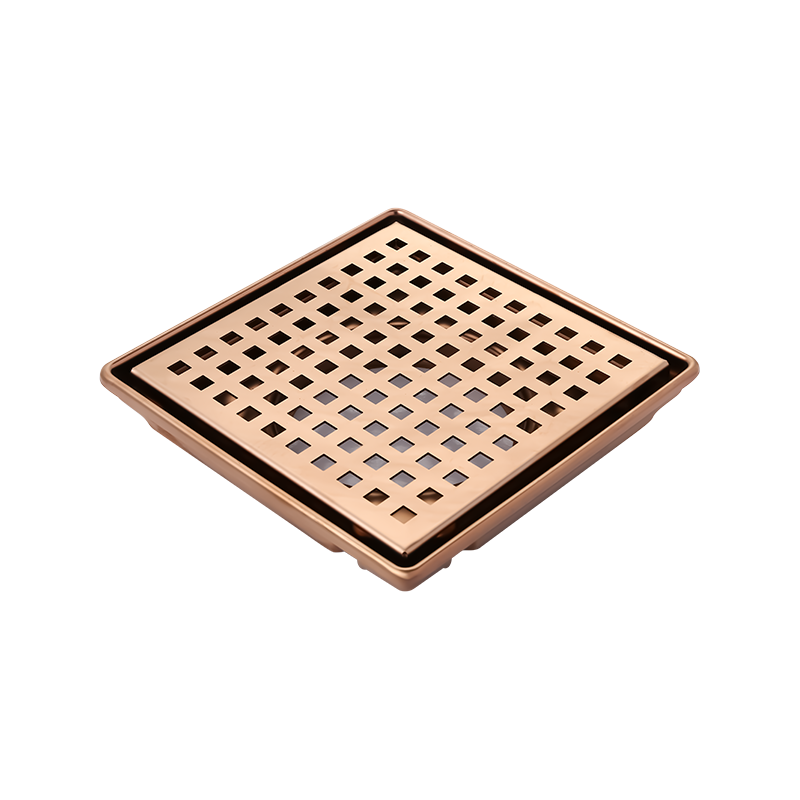

Stainless Steel Tile Drain offers a corrosion-resistant and durable solution, but its ease of installation can vary depending on soil and subgrade conditions.

Assessing how different soil types and ground conditions affect installation ensures efficient performance and long-term reliability.

Installation Considerations in Sandy Soils

Sandy soils are loose and well-draining but may pose challenges during installation:

- Excavation: Easy to dig but requires stabilization to prevent trench collapse.

- Drain Alignment: Loose particles can shift, requiring careful placement and backfilling.

- Bedding Material: A layer of gravel or sand is recommended to support the drain and ensure proper water flow.

Stainless Steel Tile Drain’s rigidity and smooth surface help maintain alignment and prevent clogging in sandy conditions.

Clay and Heavy Soils

Clay soils are dense, retain water, and can expand or contract with moisture changes:

- Digging Trench: Harder to excavate and may require mechanical equipment.

- Drain Stability: Soil expansion can exert lateral pressure, potentially deforming flexible drain sections.

- Bedding and Backfill: Proper use of gravel or sand bedding reduces pressure on the drain and ensures consistent flow.

Stainless Steel Tile Drain is resistant to corrosion, which is advantageous in wet, acidic clay soils.

Loamy and Mixed Soils

Loam and mixed soils offer moderate drainage and good stability:

- Excavation: Relatively straightforward but may contain rocks or roots that require removal.

- Drain Placement: Moderate soil cohesion provides stable support for the drain.

- Flow Optimization: Proper slope and bedding materials are still necessary for efficient water removal.

The versatility of Stainless Steel Tile Drain allows it to perform well in these soils with minimal adjustments.

Rocky or Stony Substrates

Installing drains in rocky or stony areas can be particularly challenging:

- Excavation: Hard and labor-intensive, may require heavy machinery or blasting in bad cases.

- Drain Damage: Sharp rocks can scratch or dent the drain if not properly protected.

- Bedding Requirements: A thick gravel or sand layer cushions the drain and ensures continuous flow.

Stainless Steel Tile Drain’s durability helps resist minor impacts, but careful handling during installation is crucial.

Slope and Grading Considerations

Soil type alone is not enough; slope and grading also affect installation:

- Steep Slopes: Risk of washout or misalignment; additional support structures or retaining features may be needed.

- Flat Areas: Adequate slope must be created to ensure proper water flow; improper grading can cause water pooling.

- Soil Compaction: Ensures the drain remains in place over time, particularly in heavy or shifting soils.

Stainless Steel Tile Drain can be installed effectively on slopes and flat areas with appropriate bedding and alignment.

Maintenance and Long-Term Stability

Soil conditions influence long-term performance and maintenance:

- Sandy or loose soils may require periodic re-leveling or replenishment of bedding material.

- Expansive clays can shift over time, requiring inspection to maintain proper flow.

- Mixed soils generally offer stable performance with minimal maintenance when drains are installed correctly.

- Stainless Steel Tile Drains’ corrosion resistance reduces the need for replacement, even in challenging soils.

- Stainless Steel Tile Drain can be installed in a variety of soil and subgrade conditions with proper preparation.

Sandy soils require stabilization, clay soils need careful backfilling, rocky substrates demand protective bedding, and slopes require grading adjustments.

Correct excavation, bedding, alignment, and backfill techniques are essential to ensure long-term performance and effective drainage.

With proper installation practices, Stainless Steel Tile Drain provides a reliable, durable, and low-maintenance drainage solution across diverse soil conditions.