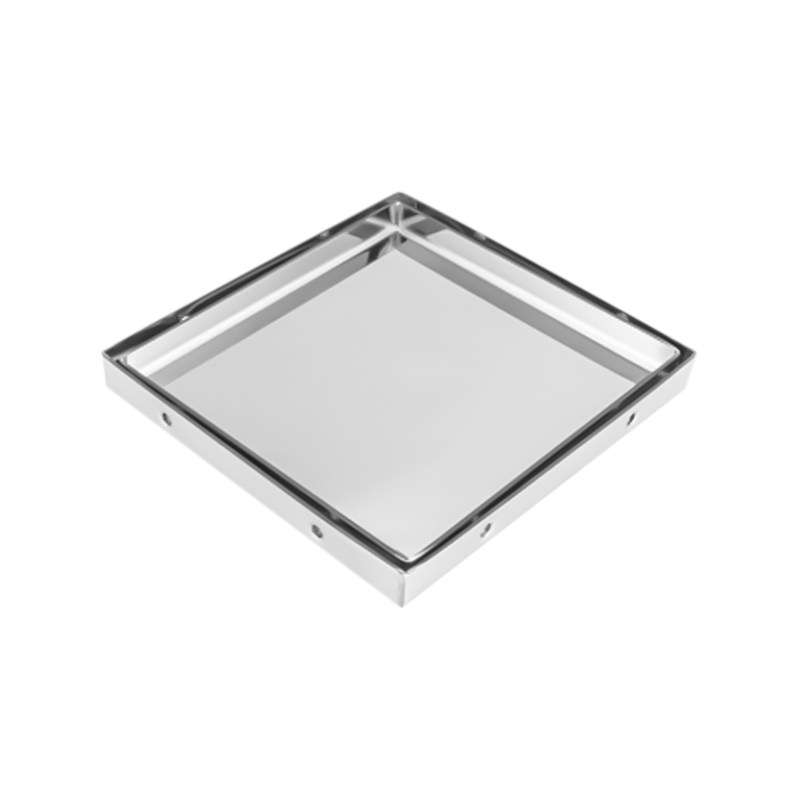

Stainless steel has long been valued in construction and plumbing for its strength, corrosion resistance, and aesthetic appeal. Among drainage solutions, Stainless Steel Tile Drain has emerged as a preferred choice for kitchens, bathrooms, and outdoor areas. However, the grade of stainless steel used in these drains plays a crucial role in determining their lifespan. Not all stainless steel performs equally under similar conditions, and understanding the differences between grades is essential for ensuring long-term durability and efficiency.

In drainage applications, 304 and 316 stainless steel are the widely used grades. Grade 304 is suitable for general indoor environments due to its good resistance to corrosion and cost-effectiveness. It can handle typical water exposure and household cleaning agents without significant degradation. On the other hand, grade 316 includes molybdenum, which significantly enhances its resistance to chloride, salt, and harsh environmental factors. This makes it ideal for areas with high humidity, outdoor installations, or proximity to coastal regions. The choice of grade directly impacts how well the drain resists corrosion, staining, and surface wear over time.

The lifespan of a stainless steel drain is largely influenced by its ability to resist corrosion. Even high-quality stainless steel is not completely immune to rust if exposed to aggressive cleaning chemicals or prolonged moisture. Lower-grade stainless steel may begin to develop small rust spots or surface oxidation, which can compromise structural integrity and appearance. Higher-grade options, such as 316, provide a stronger protective barrier against these elements, maintaining both functionality and aesthetics over many years. In environments with frequent water exposure, selecting a higher-grade material ensures a longer service life and reduces maintenance needs.

Beyond corrosion resistance, the grade of stainless steel affects its mechanical properties. Higher-grade stainless steel generally exhibits greater hardness and wear resistance, making the drain more capable of withstanding heavy loads, impact, and abrasive cleaning routines. In commercial kitchens, hotels, or high-traffic bathrooms, drains are subjected to continuous use and potential physical stress. Lower-grade stainless steel may deform or scratch more easily, creating weak points that could accelerate corrosion. Using a higher-grade material ensures structural stability, prolonging the drain’s effective lifespan.

Although higher-grade stainless steel drains are typically more expensive upfront, the investment often results in long-term savings. Reduced frequency of replacements, lower maintenance costs, and a longer functional life contribute to overall value. Consumers should assess environmental conditions, expected usage patterns, and budget constraints when selecting the appropriate grade. By investing in a stainless steel grade suited to the intended conditions, homeowners and contractors can achieve suitable performance and durability.

The grade of stainless steel used in tile drains has a direct impact on durability, corrosion resistance, and overall lifespan. While 304 stainless steel performs adequately in standard indoor conditions, 316 stainless steel offers good protection against moisture, salt, and aggressive cleaning agents. Understanding the differences between these grades allows for informed decisions that ensure the drain remains reliable, functional, and visually appealing over time. Selecting the appropriate grade of Stainless Steel Tile Drain not only enhances longevity but also provides peace of mind, reducing maintenance and replacement concerns for years to come.