When selecting drainage solutions for bathrooms, kitchens, or outdoor areas, water flow efficiency is a critical factor. Stainless Steel Tile Drain is often chosen for its durability, corrosion resistance, and sleek appearance. However, even among drains with the same nominal diameter or hole design, drainage speed can vary significantly. These differences may impact water management, cleaning efficiency, and overall user experience. Understanding the factors that influence drainage performance is essential for making informed choices.

While the hole diameter is a primary consideration in drain design, it is not the only determinant of flow rate. The spacing, shape, and total open area of the perforations affect how quickly water can pass through the drain. Even drains marketed as having identical hole sizes can differ in the number of perforations or the pattern arrangement, resulting in variations in drainage speed. In addition, the thickness of the stainless steel and the precision of manufacturing may create minor obstructions that influence water flow.

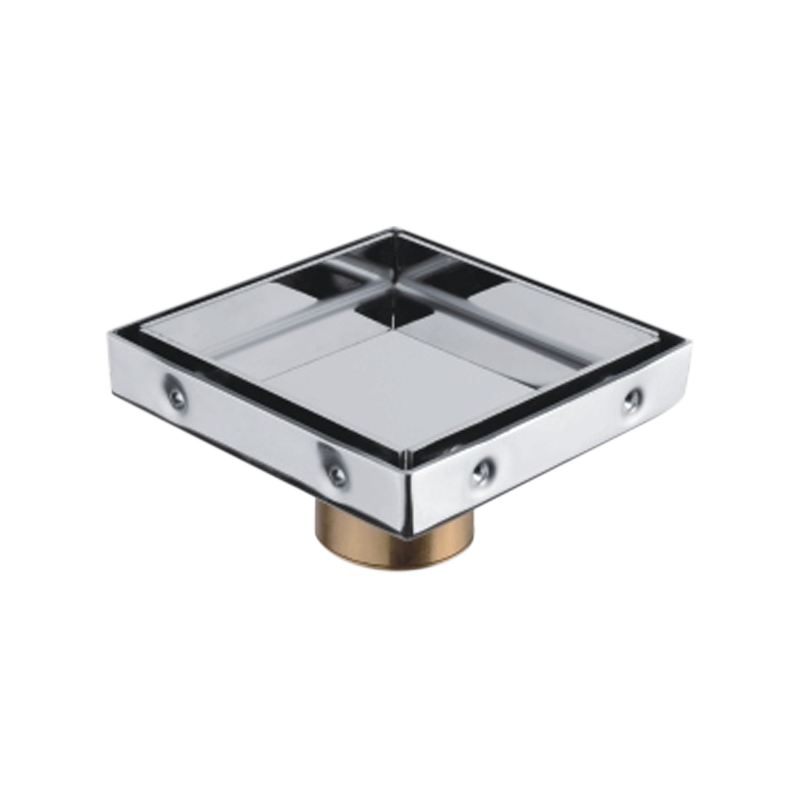

The surface treatment of a stainless steel drain also plays a role in drainage efficiency. Polished or smooth surfaces reduce water resistance and help prevent debris accumulation that could slow drainage. Conversely, rougher surfaces, even with the same hole pattern, may create micro-turbulence or minor blockages that decrease overall flow speed. This factor highlights the importance of both material quality and finishing processes in achieving suitable drainage performance.

Proper installation is crucial for consistent drainage speed. Even a perfectly designed Stainless Steel Tile Drain can perform poorly if installed on a surface with insufficient slope or uneven alignment. Additionally, environmental factors such as debris accumulation, soap residue, or mineral deposits can partially obstruct the drain holes, reducing water flow. Regular cleaning and maintenance are therefore essential to ensure that drains with the same nominal design perform as intended.

Manufacturers may produce drains with the same hole diameter but varying perforation patterns, thicknesses, and finishes. These differences can result in measurable variations in drainage speed. For example, a drain with fewer but larger holes may allow water to pass through faster, whereas a drain with many small perforations might handle debris better but drain slightly slower. This trade-off between speed and debris management is an important consideration for both residential and commercial applications.

When selecting a Stainless Steel Tile Drain, it is important to look beyond the nominal hole size and consider the total open area, perforation pattern, surface finish, and installation environment. Consulting product specifications, reviewing independent performance tests, or relying on manufacturer guidance can help ensure that the chosen drain meets the required drainage speed. In high-traffic or heavy-water-use areas, prioritizing drains with optimized hole patterns and smooth finishes can prevent water accumulation and enhance overall functionality.

Even Stainless Steel Tile Drains with the same hole diameter can exhibit noticeable differences in drainage speed due to factors such as perforation pattern, surface finish, manufacturing precision, and installation quality. Understanding these influences allows consumers and contractors to select the effective drain for their specific needs. By considering both design and environmental factors, it is possible to achieve suitable water flow, reduce maintenance, and ensure long-term performance and reliability in a variety of settings.